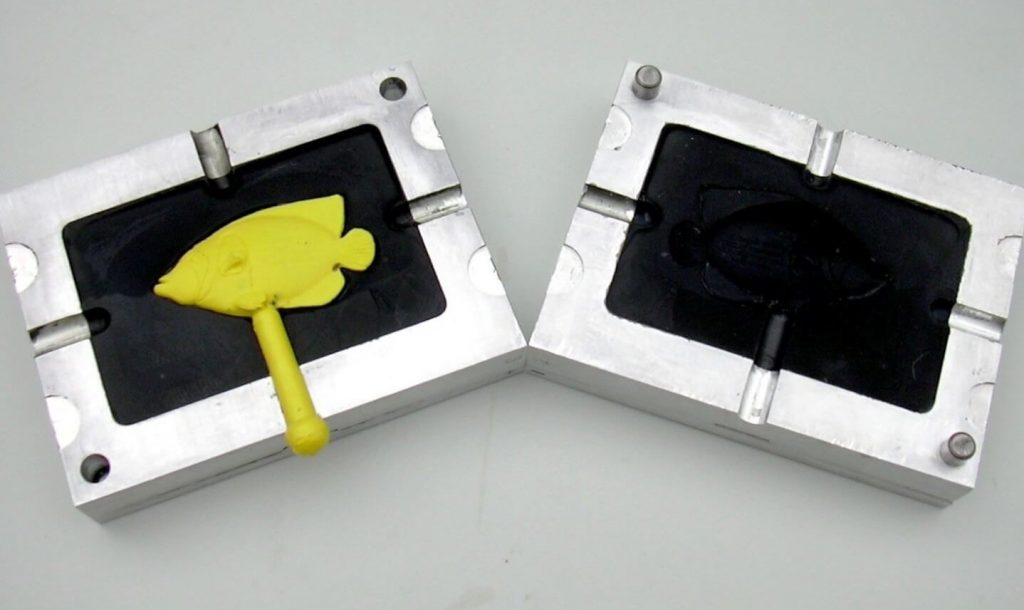

If you’re wondering what plastic injection molding is, it’s the method by which plastic particles such as thermosetting or thermoplastic polymers are melted and then poured at force into a mold chamber, further filling and hardening to form the end products.

This procedure is primarily used to produce a wide range of products, including bottle caps, automotive parts, musical instruments, mechanical parts, and so on. However, if you want to revolutionise the industry with a one-of-a-kind technique, turn to rapid prototyping for a faster outcome that will change the vision with their 3D product visualisation.

Rapid prototyping was designed to be employed primarily in the automobile industry; however, it is increasingly being employed in the medical and aerospace industries. An example of rapid prototyping, fast tooling is used in injection molding, which is probably applied in another process. But what are the advantages of adopting these tools and processes? We’ll look at it in the next part.

Helps In Giving Detail to Your Design

You can undoubtedly use these approaches to develop something new and unique. Rapid prototyping allows you to rapidly and easily convert your ideas into a 3D model. When the time arrives to build your design, the rapid prototype technique can assist you in optimizing your design to ensure a smooth production process. You can make additional designs and add to the samples whatever you missed earlier. Finally, after all of the testing and the process, your design will be completed at a low cost.

Development of the Tools

When you have completed the design development process, you will be ready to manufacture the design. Using the plastic injection molding technique, which is a sort of rapid prototyping, will assist you in lowering future manufacturing costs. Using this strategy will also save you time and money spent on tool development. If you wish to improve the measures of your tools, this technique will assist you, as will the component design.

Improves the Manufacturing Process

Even if you believe the tools are ready to be created, there will almost certainly be some faults in this process. However, using rapid prototyping or the injection molding variant will provide insight into the stages that need to be included and how the tools should be handled, which will further assist engineers in working efficiently with the tool. Using these strategies, you may also provide clients with textual instructions on operating the tool.

Use of Secondary Process

Though rapid prototyping is intended to produce the best possible outcomes, there is no harm in incorporating a secondary technique. Welding, tapping, or drilling can be implemented as secondary operations to ensure that the product you are designing with a high-tech fast prototyping process is ready for mass production.

The Final Packaging

After your tool has been created and manufactured, it is time to bundle your product before it is distributed. In this case, rapid prototyping will make sure that the product reaches the clients in perfect condition. Your product samples can also be used to specify any packaging criteria, allowing you to decrease the total packaging of a consignment.